Digital calipers are indispensable tools for precise measurements. Their versatility and ability to deliver highly accurate readings make them a favorite among a wide range of industries, from manufacturing and engineering to jewelry making and woodworking. However, even with their advanced features, improper use can lead to inaccurate results, frustration, and the wear of the tool itself.

To make the most of your digital calipers and ensure consistent precision, it’s essential to follow best practices. Understanding the common mistakes to avoid when using digital calipers can transform your measurement process and improve your overall workflows.

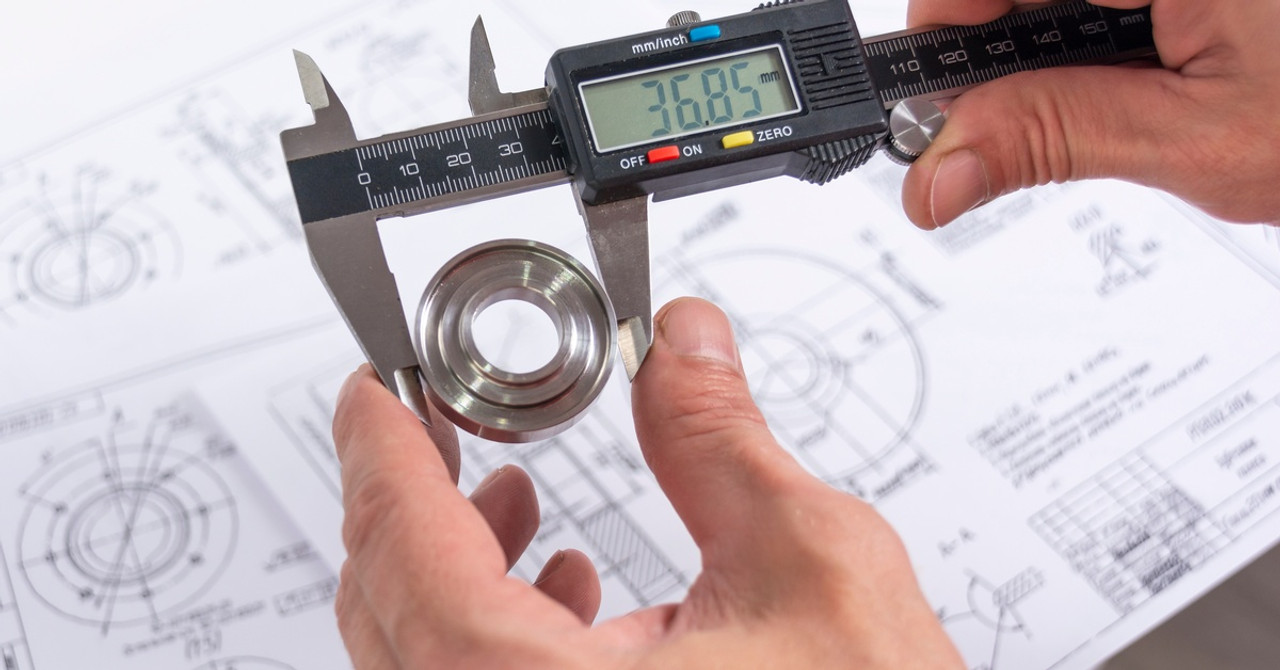

Applying Too Much Pressure

Digital calipers are precise instruments, meticulously engineered for accuracy. Applying excessive pressure during use can drastically affect results and even damage the tool. Many users assume that pressing harder will provide a more secure or exact measurement, but in reality, it can distort the object being measured or even scratch its surface. Applying too much force to the caliper’s jaws can also lead to wear and tear over time, rendering the tool less effective.

To achieve optimal results, gently close the jaws until they just touch the object being measured without compressing it. Light and steady pressure ensures the measurement reflects the true dimensions of the object and helps preserve both the calipers and the item being measured.

Incorrect Jaw Placement

Another common issue arises from improper placement of the caliper jaws on the object you are measuring. Whether you’re using the inside jaws to measure internal dimensions or the outside jaws for external dimensions, precise placement is critical. Misaligned jaws can yield distorted or misleading results. If you place the jaws at an angle or fail to ensure their full contact with the surface being measured, the readings will not be accurate.

Proper technique requires steady hands and careful alignment to ensure the jaws are flat and flush against the measurement surface. While digital calipers make the process smoother with their design, good practice and attention to detail enhance their effectiveness and the reliability of their readings.

Not Zeroing the Calipers

One of the most common mistakes made when using digital calipers is failing to zero the tool before taking a measurement. Zeroing the calipers ensures that the reading starts at zero, providing a baseline for all subsequent measurements. Without this step, the displayed measurement could include any residual offset from the previous use, leading to incorrect readings.

Always zero your calipers while they are in the closed position, ensuring the jaws are in full contact with each other. Modern digital calipers often feature a simple button for resetting to zero, making it a quick and painless step. Forgetting to do this, however, can lead to compounding inaccuracies, especially when performing a series of measurements for critical projects.

Reading the Scale Incorrectly

While digital calipers have largely eliminated the guesswork involved in reading traditional calipers, reading errors can still occur. Misinterpreting the scale, overlooking decimal points, or failing to account for measurement units can lead to incorrect conclusions.

Modern calipers often allow users to switch between metric and imperial units with the touch of a button, but this convenience comes with the responsibility of ensuring consistency in unit selection throughout a project. Always double-check your measurements, confirm the selected unit, and familiarize yourself with the caliper’s display to avoid costly mistakes caused by simple oversight.

Measuring Inconsistently

Consistency is key when it comes to taking accurate measurements, and inconsistent techniques can lead to unreliable data. This problem often occurs when measuring objects of similar sizes in a series. Slight variations in how the calipers are positioned, the amount of pressure applied, or even environmental factors like temperature can introduce discrepancies.

To maintain consistency, develop a repeatable workflow for measurements. For example, ensure the calipers are always perpendicular to the object, use a consistent level of force when closing the jaws, and take readings in a stable environment. This approach not only avoids discrepancies but also builds confidence in your data and analysis.

Neglecting Maintenance

Digital calipers are durable tools, but they still require proper care to perform at their best. Neglecting maintenance tasks such as cleaning and inspecting the tool for wear can result in reduced accuracy. For instance, burrs or scratches on the jaws can affect how well the jaws make contact with measurement surfaces, leading to errors. Dust and debris can also interfere with the smooth sliding of the caliper’s components.

Make it a habit to clean your calipers with a soft, lint-free cloth after each use. When you’re not using them, store them in a protective case to shield them from environmental damage; temperature changes may affect the calibration and accuracy of your digital calipers. Never store your calipers locked in the completely closed position—it’s best to leave a slight gap in the jaws. Keeping an eye on the condition of your calipers and immediately addressing any issues will ensure your calipers remain as precise as the day you bought them.

Improper Calibration

Regular calibration is one of the most overlooked aspects of maintaining digital calipers, yet it is crucial for ensuring ongoing accuracy. Like any precision tool, calipers can drift out of calibration over time, especially with frequent use. Many users neglect this essential maintenance step, assuming their calipers will always remain accurate. Improper calibration can lead to flawed readings that compromise entire projects.

Most manufacturers provide calibration guidelines, and there are also standardized calibration blocks available for accuracy checks. By taking a few moments to calibrate your calipers regularly, you can extend their lifespan and maintain the trustworthiness of their readings.

Improper Handling and Storage

How you handle and store your digital calipers can significantly affect their performance and lifespan. Dropping the tool, exposing it to moisture, or storing it haphazardly can cause damage that impacts functionality. Many users underestimate the importance of proper storage, leaving their calipers in toolboxes or drawers where they can get banged up or collect dirt and grime.

Always handle your calipers with care. Store them in a clean, dry case with adequate padding. By treating them as the precision instrument they are, you can avoid unnecessary wear and tear and ensure they provide accurate readings for years to come.

Collecting Data Manually

Collecting measurement data manually is not only time-consuming but also prone to human error. Many modern digital calipers offer the ability to connect to digital gage interfaces that automatically record readings. This innovation can streamline workflows, reduce errors, and allow for faster and more comprehensive data analysis.

Manually transcribing results introduces the potential for misplaced decimal points, skipped entries, or forgotten measurements. By investing in digital data collection, you save time, improve accuracy, and make it easier to manage and analyze data for complex projects.

Advanced Systems and Designs sells Mitutoyo digital calipers for precision, efficiency, and reliability. Combine our precision measurement tools with our straightforward, versatile digital gage interfaces to streamline data collection and improve the reliability of your measurement across your production workflows.